Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

WG cutter

Some of you may be familiar with Mike from Laporte, he usually comes to Indy every year. This past April while at the Indy get together he told me he was going to get rid of his Wg cutting machine. This is a machine that he constructed from misc bits and pieces that he had collected over time. I had planned on building a WG cutting machine and had even started gathering parts, but acquiring the WG machine from Mike got me 75% of the way to where I wanted to be. So thanks to Mike this has been my latest project and what I've spent most of my spare time working on. It's not finished, but after speaking with JR, he thought that some of you might be interested in seeing this contraption.

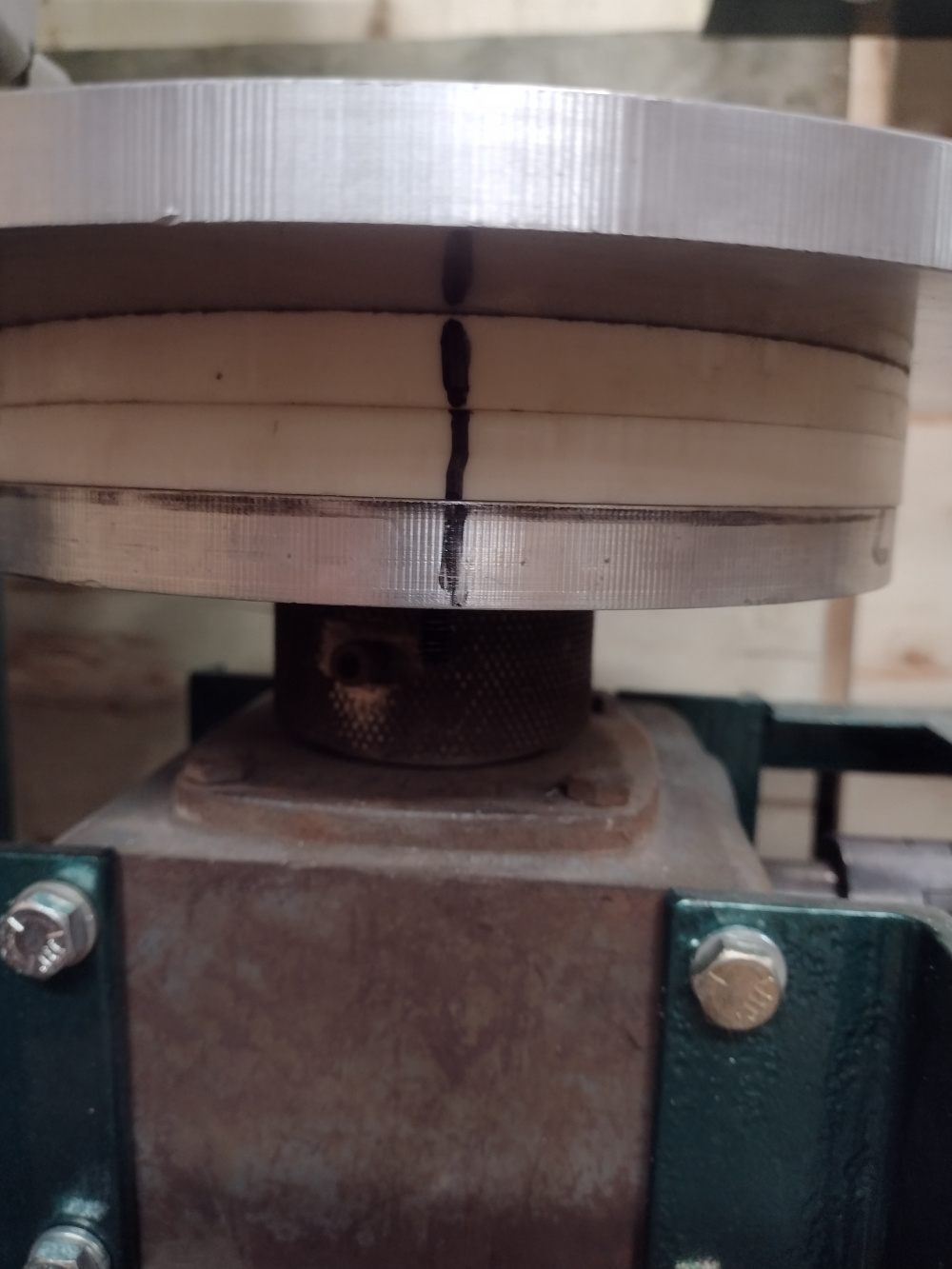

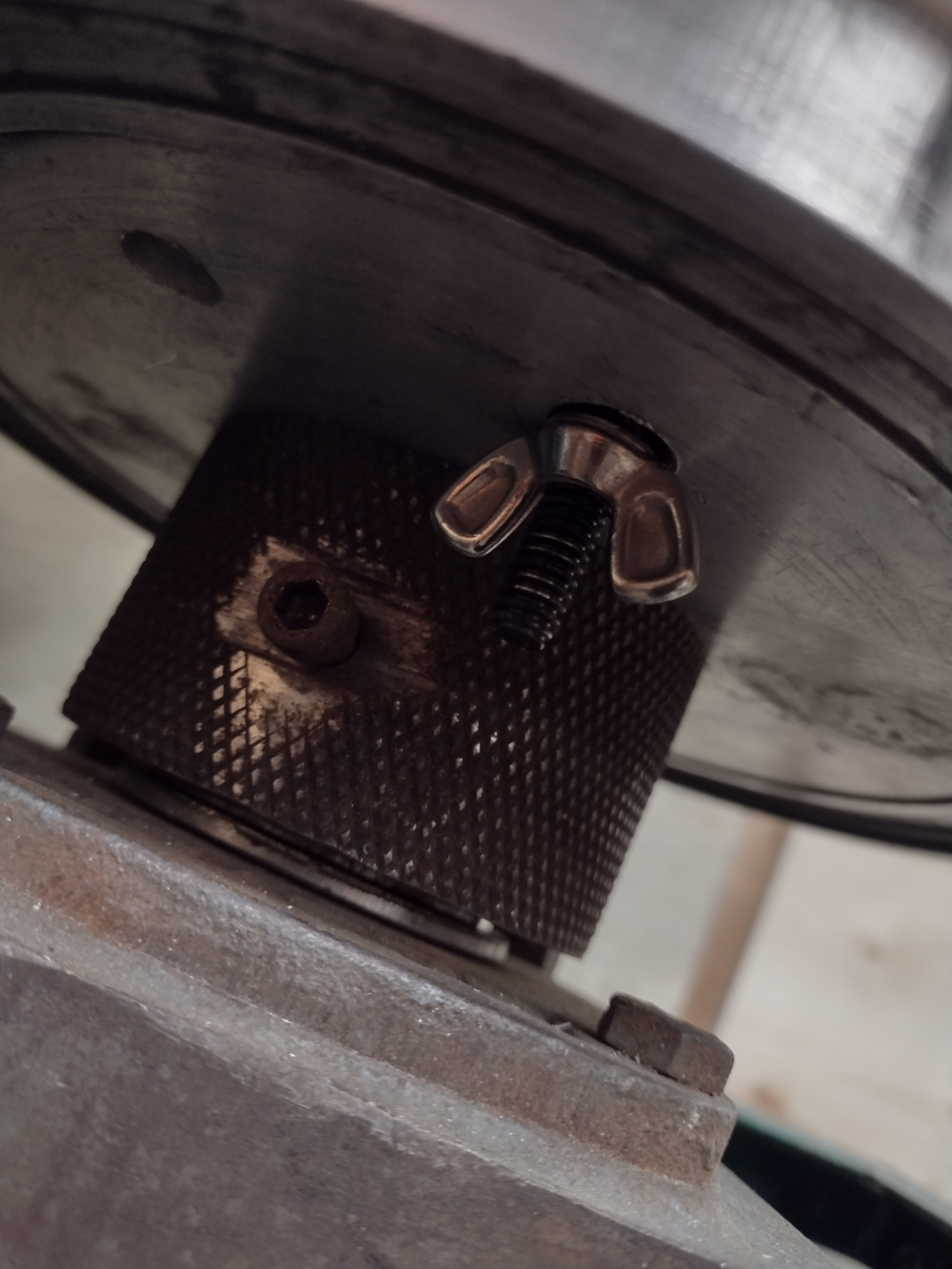

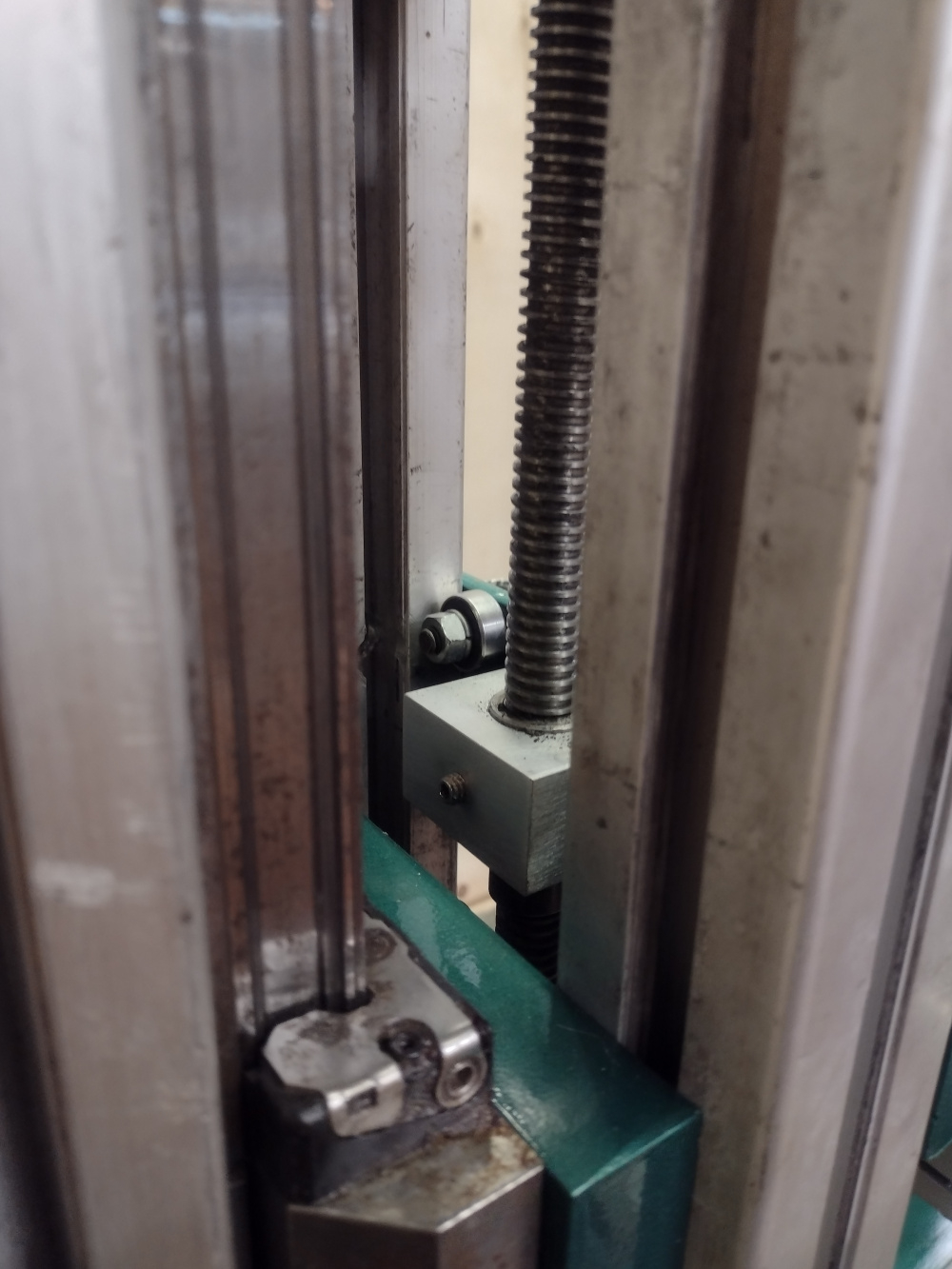

It's basically a router that rides on rails, following a wg pattern, with the wg blank being spun by a gearbox.

I'll post more photos as time permits.

Comments

^ This is the balls, man!

More pics, please . . . reminds me of a hydraulic case decapping/sizing contraption I constructed not long ago . . .

I agree with Steve. That's a contraption

Having seen it work, it was very interesting to watch too. This cut the 10" waveguides in the Veritas Mike and Chuck did about 8 years ago now. Nick has made some improvements too...

InDIYana Event Website

Maybe a video when its ready?

That's awesome Nick. Can't wait to hear what you build with it.

Looks like a rotating table that holds the material to be made into the waveguide, then a router is mechanically linked to a stylus of sorts that moves over a profile block, guiding the router as it cuts the same profile in the spinning block of material.

I hope you can integrate some sort of dust collection otherwise that thing could be the holy grail of dust makers!

This is the gear box and the 600w DC motor to drive it. The motor has a built in speed control, it just requires a 5k pot for control.

Here's a couple more. You can see the aluminum block I made for the height adjustment crank screw, and one of the four bearing on the slide, plus couple of back side shots.

I have scratch built 2 cnc machines and this is more impressive than both! This is an amazing machine.

I really want to see it work sometime.

https://www.jfcomponents.com/

Machine porn!

+1 on the video. We need to see this in operation!!!

Totally!

I'll post a short video when I finally get this thing up and running. There's still a few items to complete and the 24v power supply isn't here yet, still in transit.

Here's a few shots of the turntable platform.