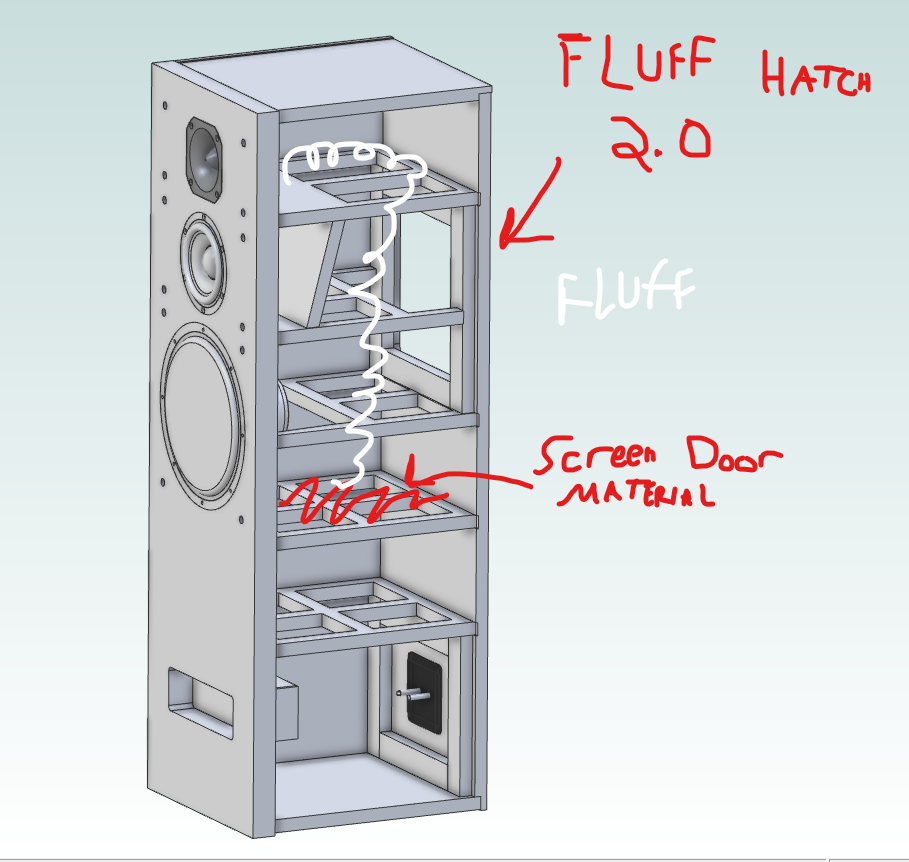

OK... so I wasn't keen on making the entire back removable. I compromised and made enough of the back removable so I could easily adjust stuffing and not feel like the leak path would be unmanageable.

I present "Fluff Hatch 2.0"

Now with improved 8.5" x ~9" opening and a cut into the brace to allow easier access top and bottom. This could probably mount XO boards on it too, but then I would still need to mount binding posts low, so maybe not as much effort saved!

I like the hatch idea with the x-o on the bottom. I've done a few with a removable bottom panel which is a bit easier to construct. The removable bottom panel plus the driver openings should give you decent access.

I recessed the bottom panel and externally mounted the x-o on the bottom panel which was a bonus.

Comments

OK... so I wasn't keen on making the entire back removable. I compromised and made enough of the back removable so I could easily adjust stuffing and not feel like the leak path would be unmanageable.

I present "Fluff Hatch 2.0"

Now with improved 8.5" x ~9" opening and a cut into the brace to allow easier access top and bottom. This could probably mount XO boards on it too, but then I would still need to mount binding posts low, so maybe not as much effort saved!

Yep - use nylon screen material - hot glue it into place.

I like the hatch idea with the x-o on the bottom. I've done a few with a removable bottom panel which is a bit easier to construct. The removable bottom panel plus the driver openings should give you decent access.

I recessed the bottom panel and externally mounted the x-o on the bottom panel which was a bonus.