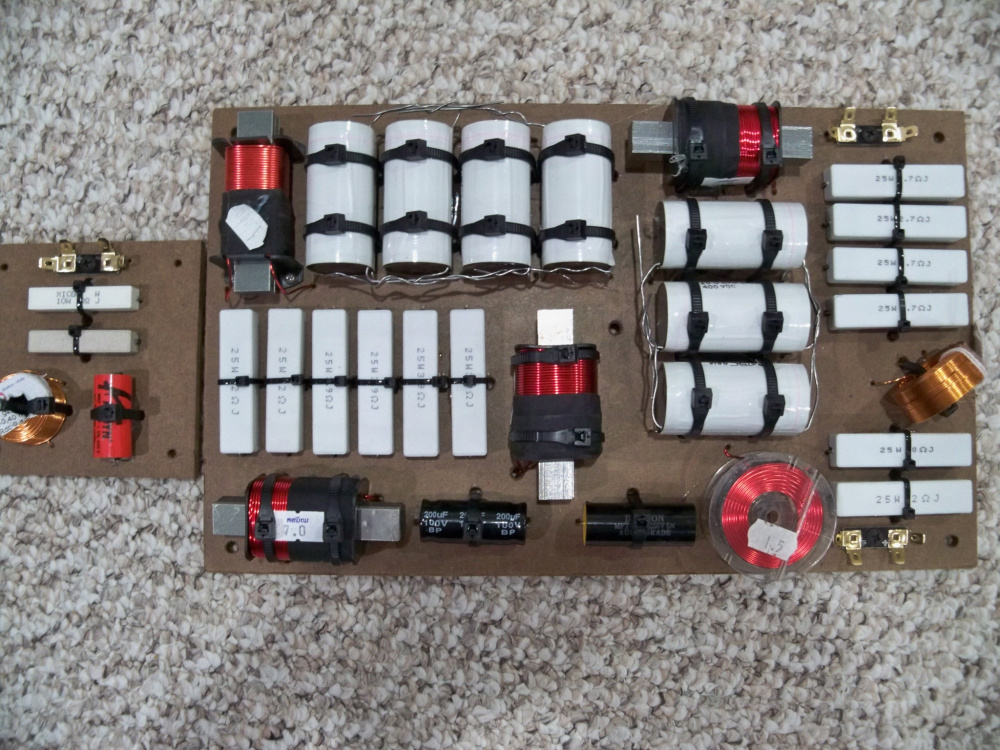

Here's the crossovers, they aren't as complex as they may appear. The white caps are paralleled to realize the size that's required and the resistors are all series or parallel to increase their power handling, also two of the laminate core inductors are connected in series to once again get the value that I was looking for. The tweeter is just a 2nd order electrical with a lpad and the mid is likewise 2nd order electrical with a resistor in front and a lpad behind. The oddball is the woofer which utilizes a 3rd order with lcr impedance compensation.

Nice attention to detail.

Once again, I question the proximity of the woofer to inductors.

Is anyone else mindful of crossover location because of it? I know sometimes it's unavoidable.

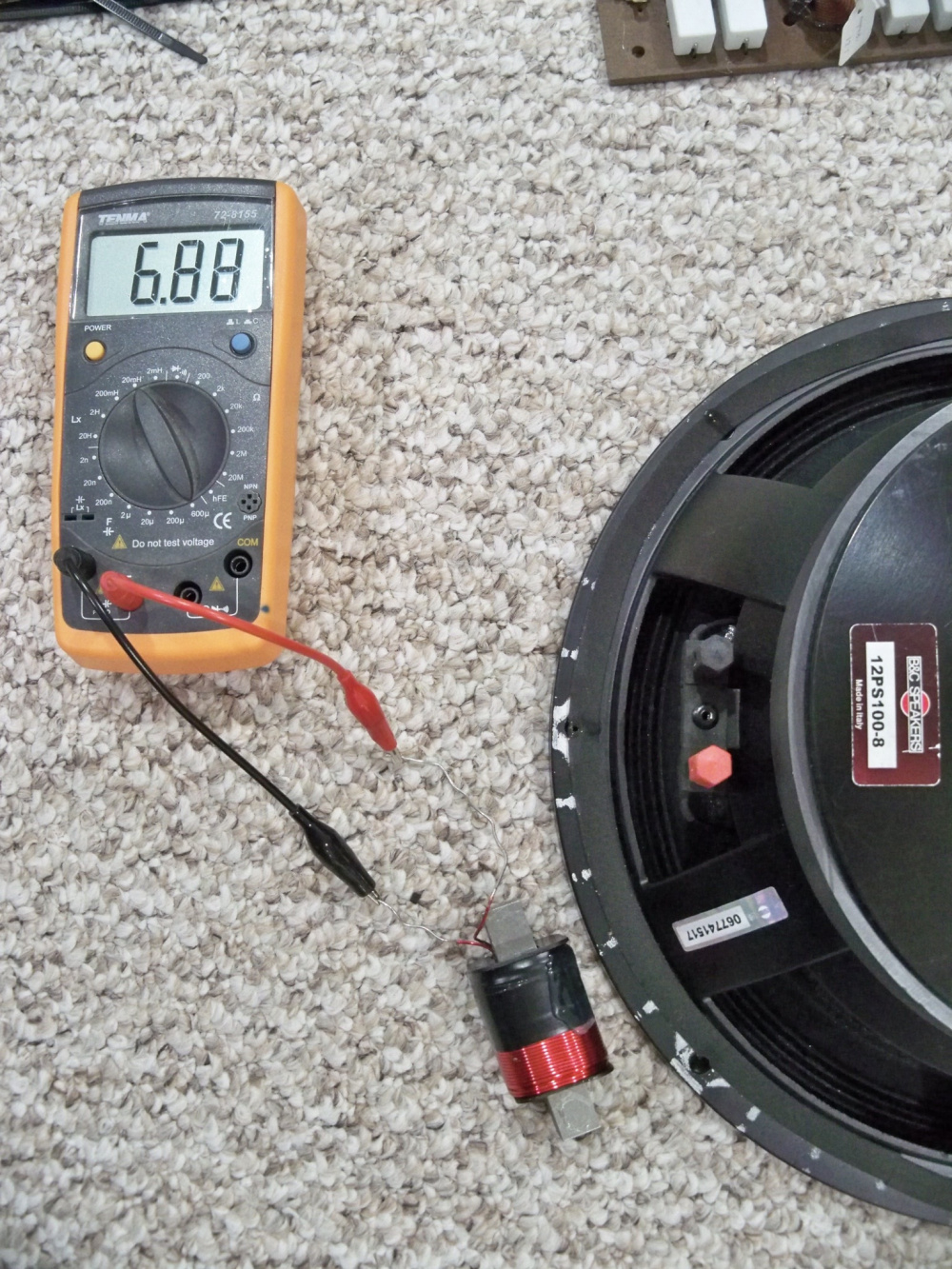

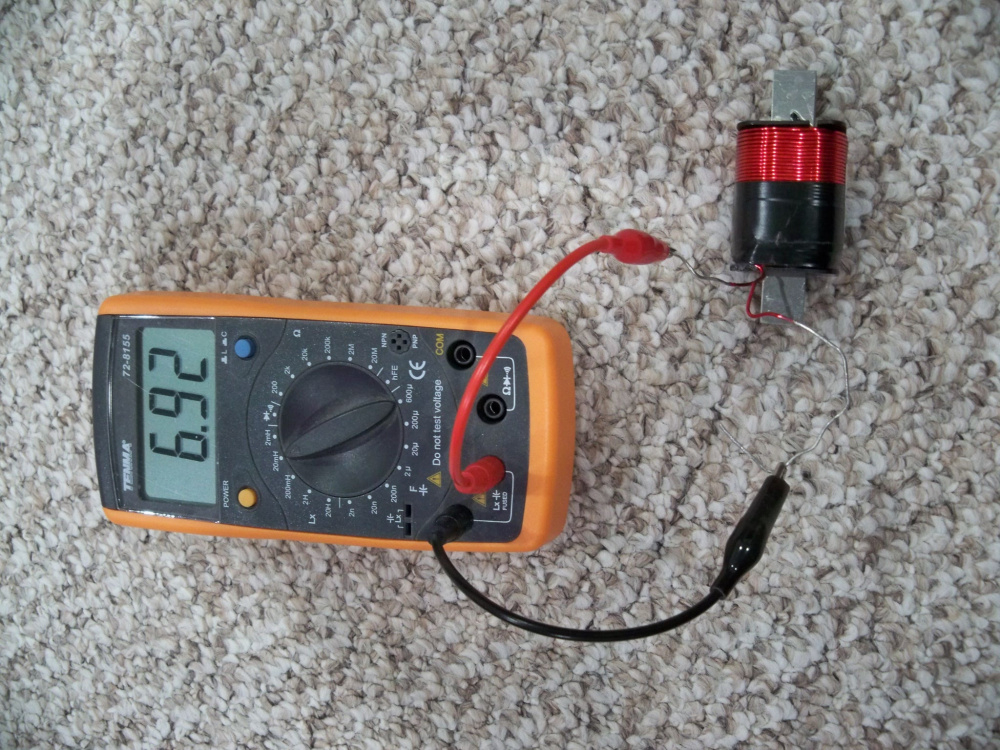

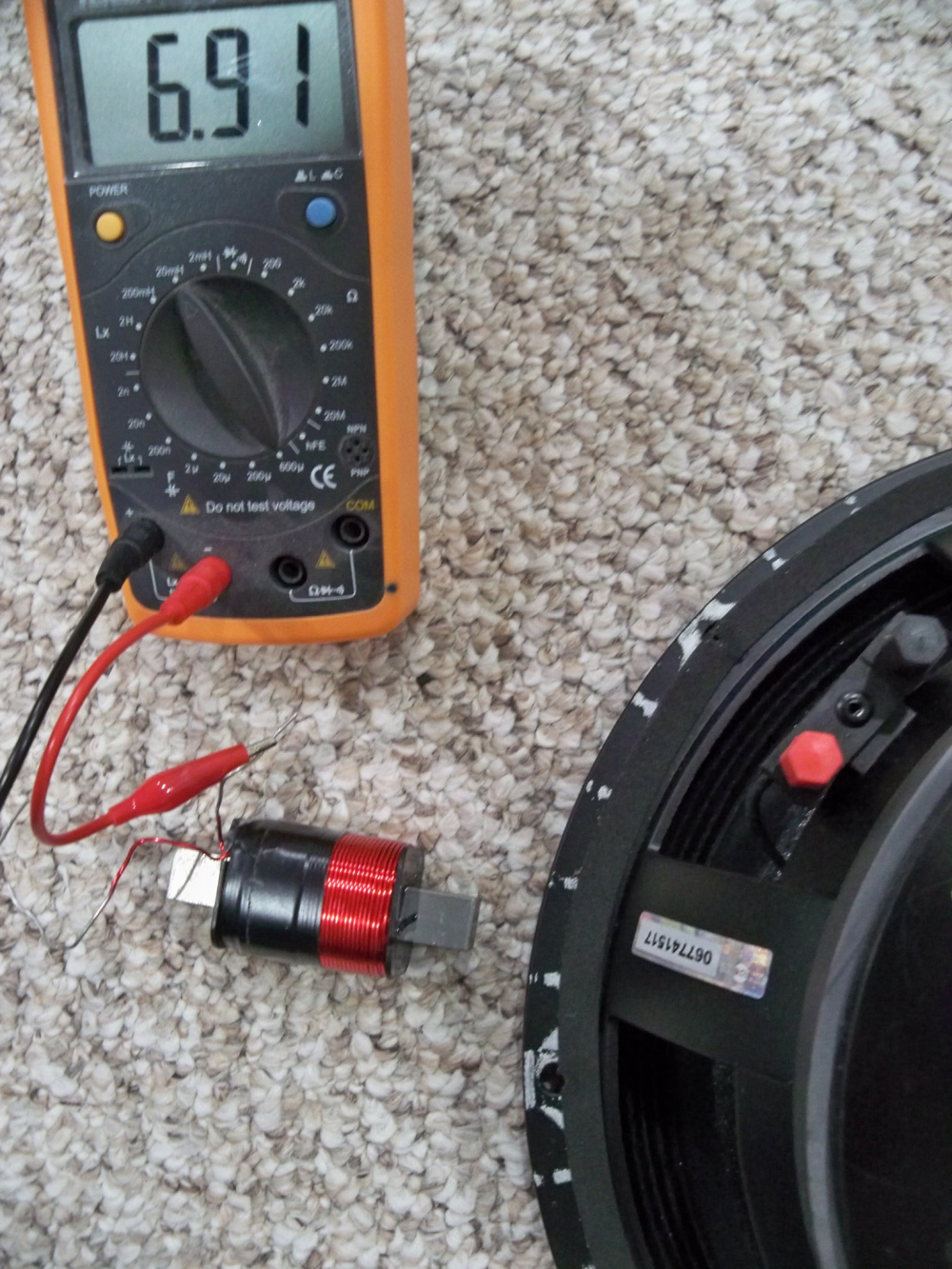

Okay, so Eric got me thinking and I decided to do a quick test. I used a 6.8mh coil, because...it was the first one that I grabbed. I just used the cheap meter, but if anyone wants I can use a GW Instek lcr821 which can test in a frequency from 100hz to I believe 200khz.

When I did the Synchaetas, the LPcoil had to be 1.1mH in the Minimus7 aluminum cabs, as the aluminum derated them to the proper 0.9mH value. In the same project, I used a rod-cored coil for the notch across the midbass. I was going to solder the LC directly across the midbass' terminals, but when I did that, the magnet in proximity to it virtually nullified its value when close to it. I ended up using air cores for that reason.

Thanks for the info. Interesting stuff. Curious, I pulled a 2mH ferrite core inductor (dcr .30 ohms) from my junk box, set a TB W6-1139SIF face down on the carpet, and hooked the inductor to DATS V2. I took about 20 measurements. At a distance of 3 inches, 2 inches, 1 inch, or even 3/4" from the magnet, the inductor always measured about 2mH regardless of orientation. When I got closer to the magnet than 3/4", the inductor started bumping up to 2.3mH. With the inductor placed directly on top of the magnet, I got 2.5mH in one orientation and 1.1mH by rotating the inductor 90 degrees (wow, must have criss-crossed the magnetic poles or something like that).

Also, when I pressed the inductor directly up against the metal speaker flange (about 2 inches from the magnet), the inductor bumped up to 2.17mH. But the inductor stayed at 2mH if I moved it slightly away from the flange. Looks like I am getting pretty much the same type of results that you did.

So to wrap this up, it appears that air core inductors are less susceptible to value change than laminate core inductors, and core orientation does matter, with the most effect happening with the core pointed at the driver, but the coil will be fine as long as there is an inch or two between it and the driver. I can't see any of this being a problem unless you're building a super small speaker, just don't zip tie your coils to your woofers.

Comments

That is beautiful, and I need to get off my ass and build a set using those new fangled GRS 12" drivers.

Hell yes, JR the world needs more monkey coffins.

Far out, man! Those are groovy in the most boss way!

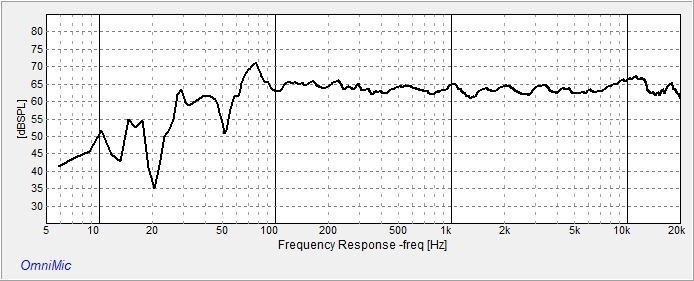

P

reliminary on axis measurement.

Here's the crossovers, they aren't as complex as they may appear. The white caps are paralleled to realize the size that's required and the resistors are all series or parallel to increase their power handling, also two of the laminate core inductors are connected in series to once again get the value that I was looking for. The tweeter is just a 2nd order electrical with a lpad and the mid is likewise 2nd order electrical with a resistor in front and a lpad behind. The oddball is the woofer which utilizes a 3rd order with lcr impedance compensation.

Crossover porn!!!! I love it!

Nice attention to detail.

Once again, I question the proximity of the woofer to inductors.

Is anyone else mindful of crossover location because of it? I know sometimes it's unavoidable.

The full monty.

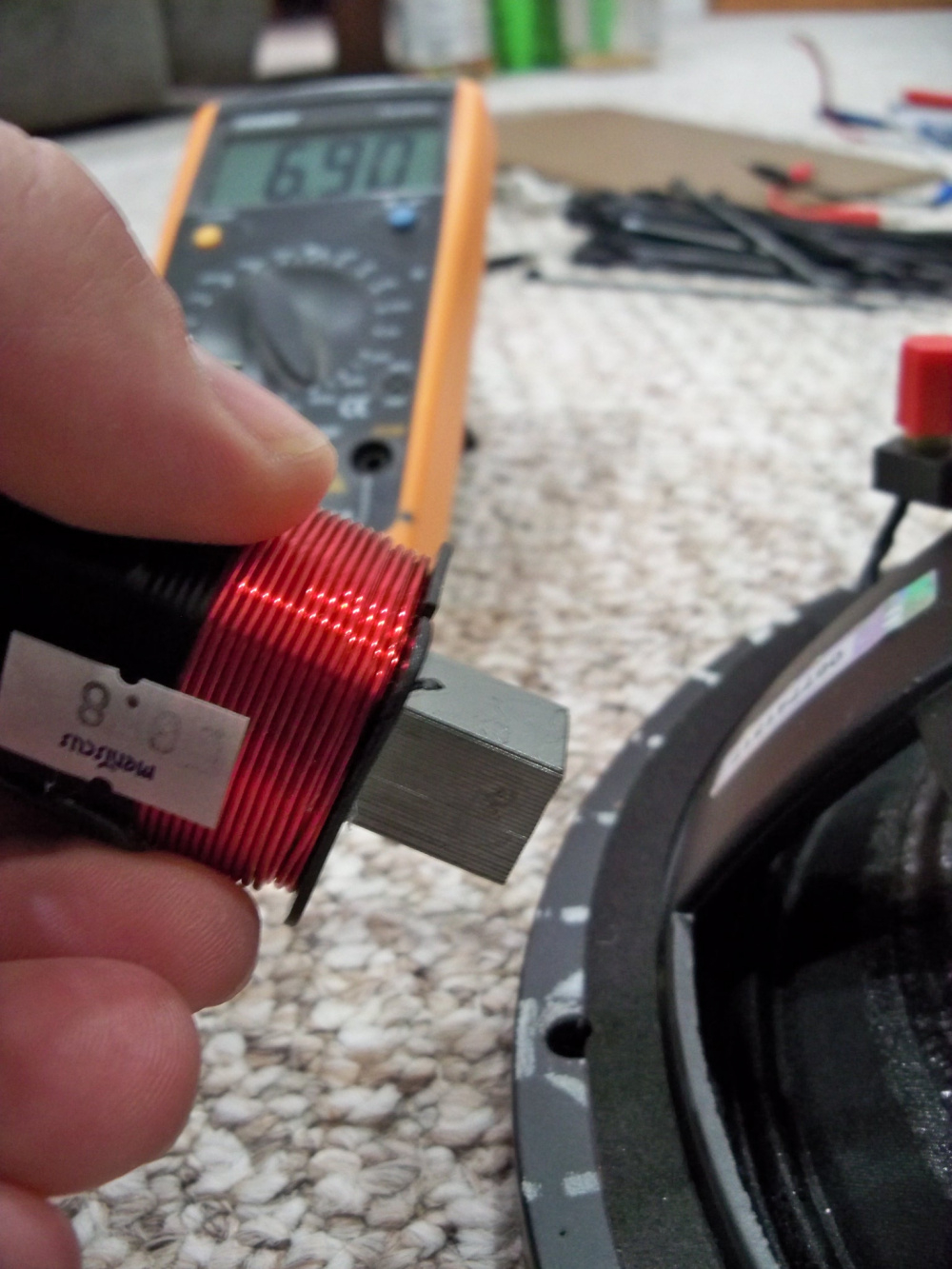

Okay, so Eric got me thinking and I decided to do a quick test. I used a 6.8mh coil, because...it was the first one that I grabbed. I just used the cheap meter, but if anyone wants I can use a GW Instek lcr821 which can test in a frequency from 100hz to I believe 200khz.

The first picture is the coil laying right up against the magnet, and the second photo is about one inch away.

Are those ASC 30uF caps? I bought a shitload of them a few years ago.

They're ASC 20uf, and I think that I bought 100 of them also a few years ago. Does 100 count as a shitload?

Yes, it sure does.

Thanks for that.

Guess it's more important for space between inductors than close to other metal / magnet stuff?

When I did the Synchaetas, the LPcoil had to be 1.1mH in the Minimus7 aluminum cabs, as the aluminum derated them to the proper 0.9mH value. In the same project, I used a rod-cored coil for the notch across the midbass. I was going to solder the LC directly across the midbass' terminals, but when I did that, the magnet in proximity to it virtually nullified its value when close to it. I ended up using air cores for that reason.

InDIYana Event Website

Does it make any difference if you rotate the inductor 90 degrees either one way or another when close to the magnet? Or if you rotate the magnet?

In my case, it did not matter.

InDIYana Event Website

I kinda wondered if orientation has any different effect, get that meter back out Nick🤔

I'll check in a little while guy's.

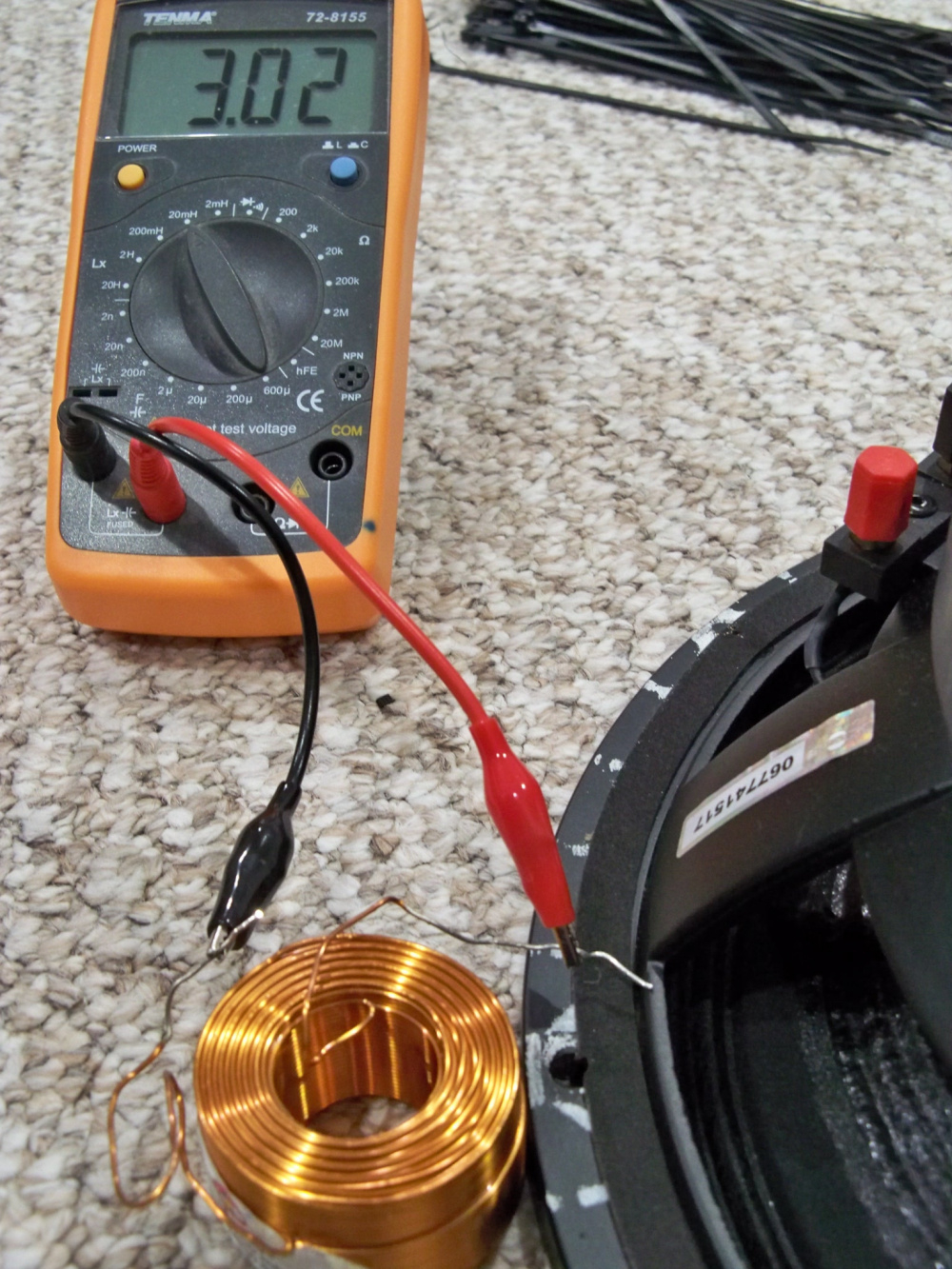

Here we go, a baseline

1/2" or so away

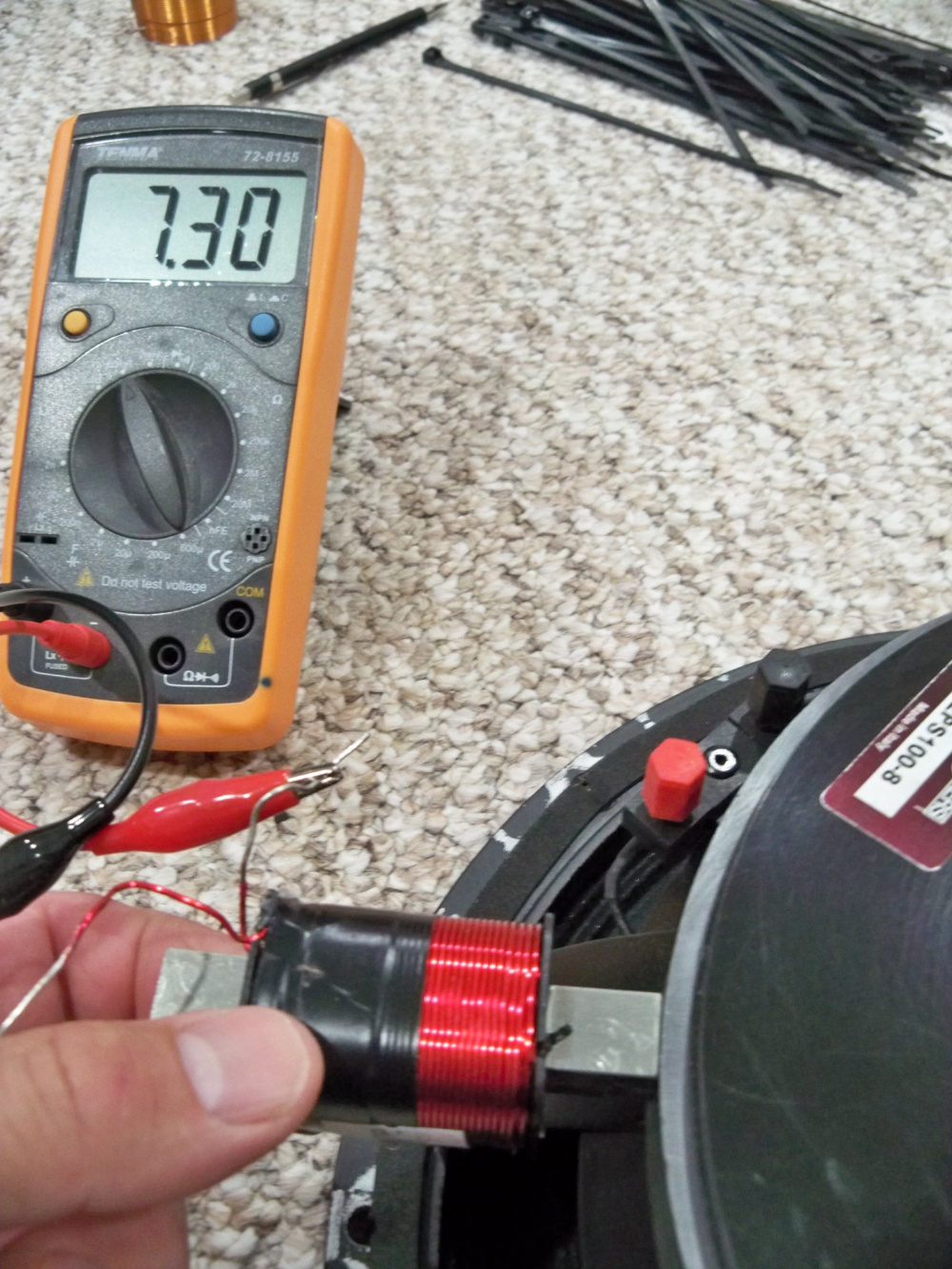

touching the basket

Touching the magnet

About one inch away

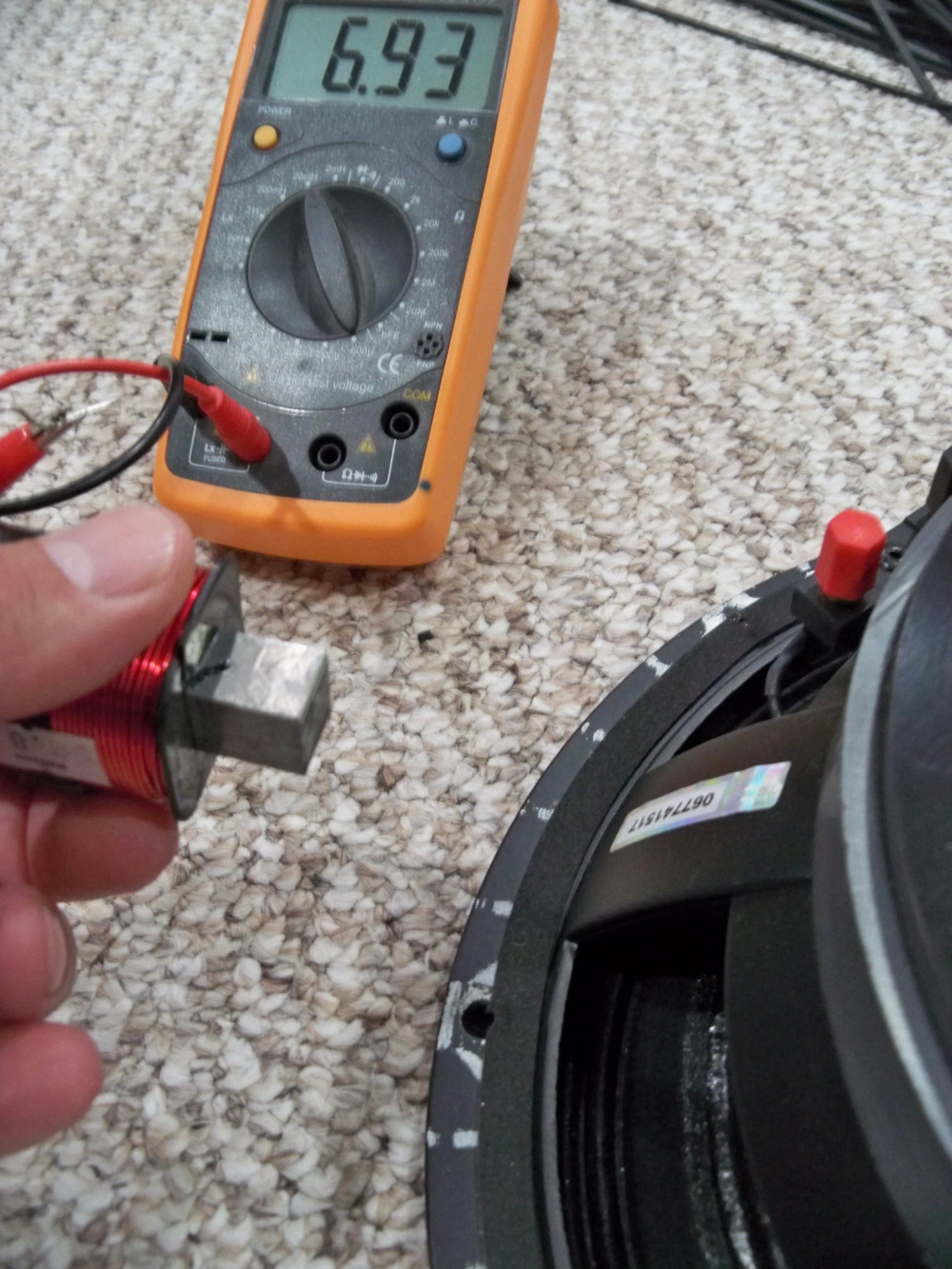

At magnet height, about three inches away

and angled

Thanks for the info. Interesting stuff. Curious, I pulled a 2mH ferrite core inductor (dcr .30 ohms) from my junk box, set a TB W6-1139SIF face down on the carpet, and hooked the inductor to DATS V2. I took about 20 measurements. At a distance of 3 inches, 2 inches, 1 inch, or even 3/4" from the magnet, the inductor always measured about 2mH regardless of orientation. When I got closer to the magnet than 3/4", the inductor started bumping up to 2.3mH. With the inductor placed directly on top of the magnet, I got 2.5mH in one orientation and 1.1mH by rotating the inductor 90 degrees (wow, must have criss-crossed the magnetic poles or something like that).

Also, when I pressed the inductor directly up against the metal speaker flange (about 2 inches from the magnet), the inductor bumped up to 2.17mH. But the inductor stayed at 2mH if I moved it slightly away from the flange. Looks like I am getting pretty much the same type of results that you did.

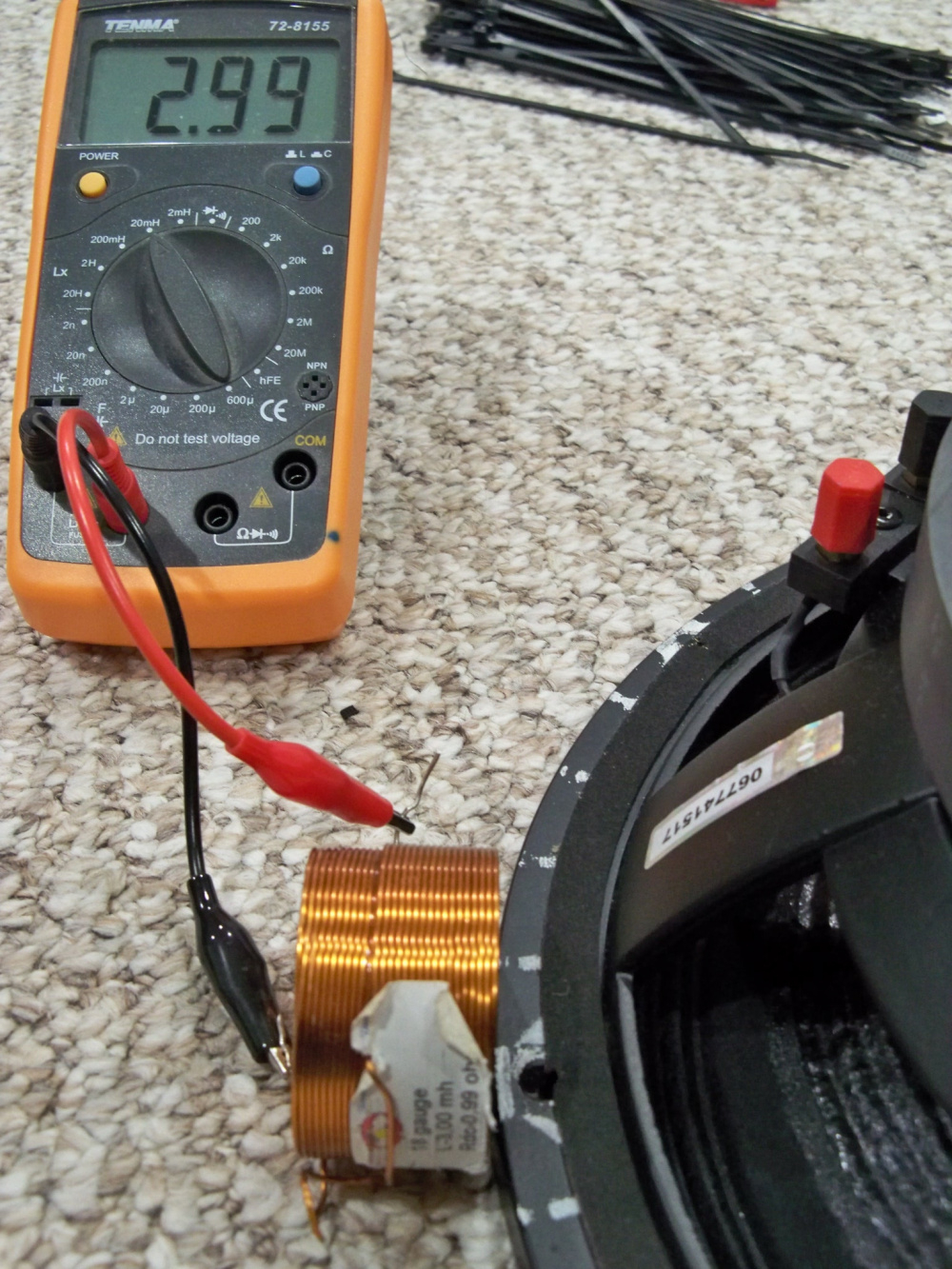

Here are the air core readings.

Against the frame core perpendicular

Against the frame, core pointing at the frame.

Against the magnet, core pointing at the magnet.

Against the magnet core perpendicular.

pointing at the magnet, but a space.

So to wrap this up, it appears that air core inductors are less susceptible to value change than laminate core inductors, and core orientation does matter, with the most effect happening with the core pointed at the driver, but the coil will be fine as long as there is an inch or two between it and the driver. I can't see any of this being a problem unless you're building a super small speaker, just don't zip tie your coils to your woofers.

Excellent, thanks

It might be time for "Weight Watchers"

BEEFCAKE!!!!!!!!!!!

InDIYana Event Website