Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

Please review the site Rules, Terms of Service, and Privacy Policy at your convenience. Rules, TOS, Privacy

Get familiar with the reaction system: Introducing the Reaction System

Bending laminate

I've seen countertops with some pretty freakishly tight radius bends (somewhere around 1/2" radius) on the outward horizontal edge that the laminate bends around. I know they must use some sort of heat wire/tape that runs the length of the bending press they use. I've also seen folks use a regular iron to bend a narrow laminate edge band around a couple inch radius. But what about bending a sheet around a radius the length of a speaker tower?(1.25-1.5" radius)

Think using an iron with laminate over contact cement would work somewhat similar to the tite-bond/heat activated glue with veneer? Anyone have experience with this sort of thing?

Comments

I think that is likely a job for a heat gun, heated steel pipe, or maybe a torch if you are careful. I do not think an iron will be able to do it

InDIYana Event Website

https://youtube.com/watch?v=MryiiCEVOLE

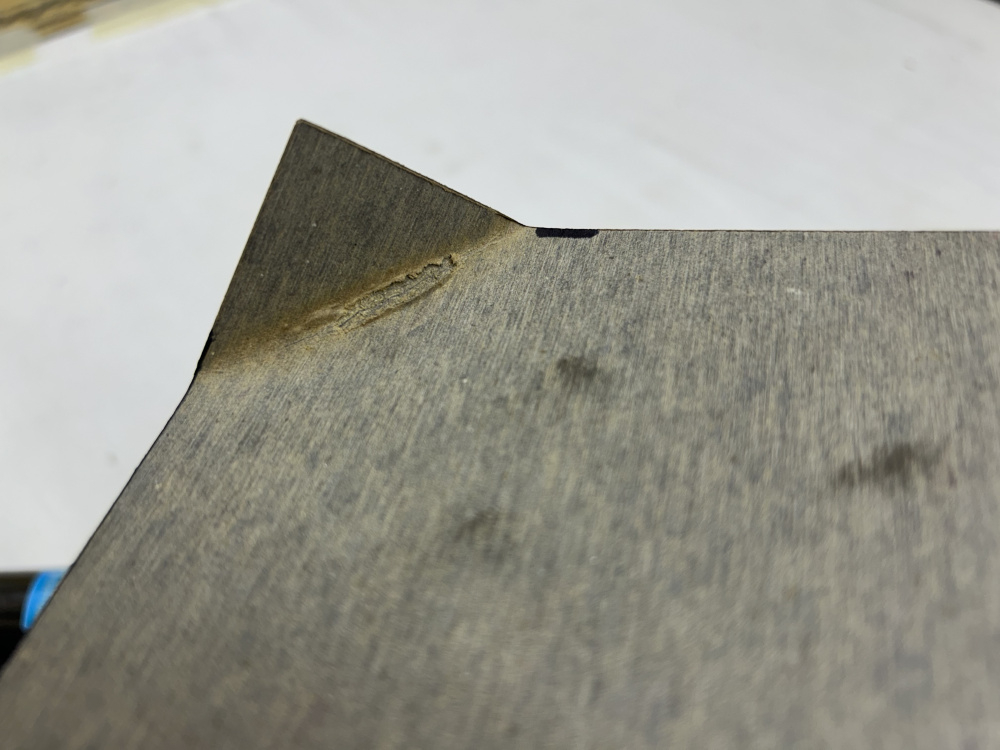

I think it’s actually called Postforming. Which for us DIYers is a pain in the ass. I’ve tried it with all types of heat. It either blisters the front or popped the back so basically it starts to delaminate the lamination. But I do think the best way to do. It is with a pipe that is heated, and then you bend it around that pipe of the radius that you want. Take your time heating it. Here is an example of some laminate had laying around with a small little torch.

https://www.jfcomponents.com/

When I used to make laminate tops, when the product was thicker, I would use a heat gun on the face side at a distance to slowly heat it while applying pressure to conform to the radius. It was the counter edge, so 1.5 inch wide. I like the pipe idea. From my understanding it is multiple layers of brown paper bonded together with phenolic resin. the pattern is printed on a white paper and a clear wear layer is applied. Heat the core so the brown can compress before tension causes the face layer to fracture.

Postforming type of plastic laminate has to be used (vertical or standart grade do not work ). I used heat gun on face and glued loose end with white wood glue ( masking tape can be used to cover 3/4" of the loose end ).

Just asking due to this load of laminate i got from Clay. Right after getting a router table setup so i can do larger than 1/2" radius. Such is life. Sounds like it'll be as much of a pita as i originally thought.. and decent risk of failure. So ill save it for projects with straight corners unless i get the itch to try anyway.