. . . It appears to spec 2.2uF, but larger may be prudent to allow more bass through? I did test it with 2.5uF temporarily before the 2.2uF caps shipped in. There is plenty of space on the board to accomodate. But be careful when hooking this up to other equipment since there are no input caps. And I don't see any bleeder resistor for the power supply cap/s so the spicy voltage could stick around for quite a while.

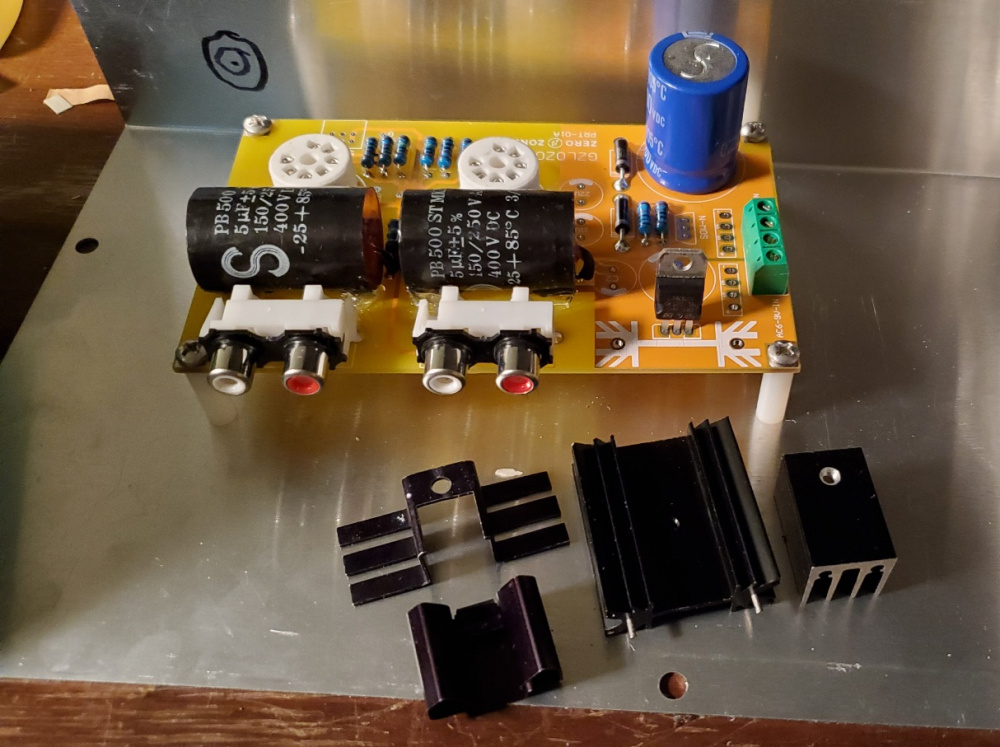

I would think that 2.5uF should be more than enough. Just make sure the voltage rating is well above the measured power supply voltage. For instance, if we connect the preamp to a power amp with a 10K input impedance, then the -3dB low frequency roll off point caused by the cap would be 1/(.0000025 x 10000 x 6.28) = 6.37Hz. That should be good enough. I dug through my stash of PP caps and found two Solen 5uF 400 PP caps that fit the PCB perfectly without hitting the ceramic tube socket or RCA jacks. 1/(.000005 x 10000 x 6.28) = 3.18Hz -3dB.

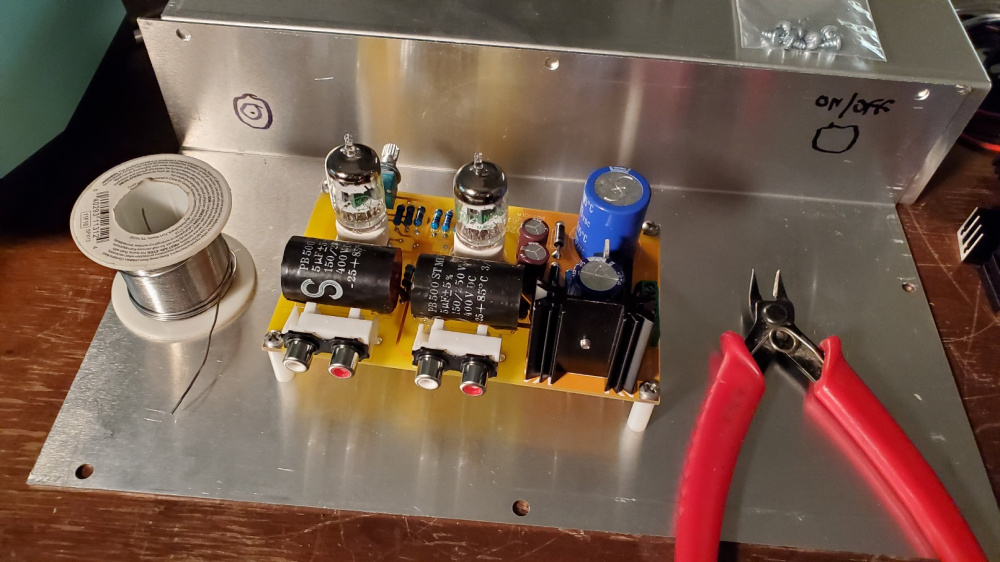

I have an unused Bud box from a previous abandoned project, so I decided to press it into service for my "3rd" build. It is a Bud CU-622-A and measures 12" x 6" x 2.5" (WxDXH). For layout purposes, I temporarily put a few parts on the PCB (not soldered) to see how everything would fit. As viewed from the back, I positioned the xformer on the extreme right hand side and the PCB on the extreme left hand side. This keeps the xformer 7 inches away from the nearest 6J1 tube. I am hoping that this is far enough to avoid any hum pickup issues. I plan to drill four 1/2 inch holes on the left back side of the bud box for the RCA input/output jacks. Then I will cut a larger rectangular hole in the right back side of the bud box for the combo IEC/fuse power inlet.

For the volume control, I plan to add an extension to reach the front panel using a length of 1/4-20 machine screw material cut to the right length (about 2.5" or so). In the photo, I simply taped a 1.5" long flat head 1/4-20 machine screw to the end of the volume control, just for illustration purposes. I will probably need to epoxy a nylon bushing to the front panel to act as a bearing for the extended shaft. Will also epoxy the machine screw to the volume control shaft as well. Hopefully the epoxy will not crack or break off in operation.

I will be using 1/2" tall aluminum standoffs, which gives about a 1/16" clearance to the top of the tube when I put the top cover on. This should work out OK. Some tubes might be a little bit taller, but if they hit the top panel, I will drill two small holes in the top of the Bud box for clearance. I will not be able to see the tube filaments in operation, so I will be adding a pilot light type on/off switch to the front panel. This would go on the extreme right side with short leads to the xformer area.

Let me know what you think of this layout. It is still a work in progress. I plan to populate the PCB today and then drill out the bud box tomorrow.

I think it would look cool if the tube was going out the top. You could mount larger components like capacitors on the bottom to get the tube closer to the top.

@kenrhodes said:

I think it would look cool if the tube was going out the top. You could mount larger components like capacitors on the bottom to get the tube closer to the top.

Good idea. I took some measurements and discovered that I can raise the PCB another 3/4" before running into any capacitor or heat sink clearance problems. The tallest item on the PCB, other than the tubes, is the filament power supply heatsink for the 7806 regulator. But if I replace that heatsink with a shorter one, I can raise the PCB as much as 1.25" with no problems.

@Tom_S said:

Looks good! I have some shaft extensions and bushings I could send you, but they won't work with that knurled shaft.

Ya, the slotted, knurled shaft would be crushed by the set screw. My plan is to use some inexpensive "Hillman Fastener" type nylon sleeves and bushings that have an approximate 1/4" ID. I'll cut a slot in the nylon sleeve and slip it over the knurled shaft and extension, then pour some 5 minute epoxy into the slot and joint. If I can keep everything in perfect alignment as the epoxy sets, I should be good to go.

Very warm? sure. Not so hot that I couldn't leave my finger there indefinitely. I understand, it comes with the heatsink so why not use it right? But if it is a space issue, and leaving it bare makes you uncomfortable; I'd say mounting it to the chassis should give it a nice cushy life.

Thanks, Drew. I agree. It looks like the tall heatsink supplied with the kit is overkill. I have 3 other much shorter T0-220 style heatsinks that I can substitute. Any one of them will fit the existing PCB space and solve the problem.

Edit: Oooops, looks like I have the 7806 in backwards on the pic. It is not soldered in place yet. I accidently put it in backwards before I snapped the photo.

Here is a visual comparison of the original tall heatsink verses a much shorter one. This will allow me to push the PCB up an additional 1/2" or so for a nice tube glowing effect. Almost ready to give it the smoke test.

Bill , could you have reversed the tube socket install to the bottom of the board to bring those tube out of the chassis a little more? Not sure if that makes sense.

@Nicholas_23 said:

Bill , could you have reversed the tube socket install to the bottom of the board to bring those tube out of the chassis a little more? Not sure if that makes sense.

I thought about that too, but the pinout for the tubes would be reversed. Probably easier to just mount the other tall parts from underneath instead.

If the jacks were left off and wired in remotely, could add input caps in-line. Though I don't know enough about tubes. Is grid impedance influenced by the other operating voltages? If not the original kit updated value of 3.3uf would work? But maybe higher voltage spec to withstand a worse case scenario.

A big thanks to DrewsBrews for giving me this circuit - I don't know too much about tube circuits or any circuits in general. So looking to see if I should go ahead and build it as is or some improvements can be made.

@DrewsBrews said:

If the jacks were left off and wired in remotely, could add input caps in-line. Though I don't know enough about tubes. Is grid impedance influenced by the other operating voltages? If not the original kit updated value of 3.3uf would work? But maybe higher voltage spec to withstand a worse case scenario.

My understanding would be that the input impedance of this preamp would be the 50K pot in parallel with the 1 meg grid resistor (1/((1/1000000+1/50000)) = 47.619K ohms. This resistive input load would be modified somewhat at very high frequencies by the 6J1 tube's plate to grid (miller effect) and grid to cathode capacitances.

So if you placed the input capacitor externally, then the cap would basically see a 47.619K load. Using a 3.3uF input cap, the -3dB low frequency roll off would be 1/(6.28 x 47619 x .0000033) = 1.01Hz. This is overkill. A 1uF cap should be more than enough: 1/(6.28 x 47619 x .000001) = 3.3Hz (-3dB).

On the original 6J1 preamp kit, we did not need to boost the input cap from 1uF to 3.3uF (C9, C11). We could have left it at 1uF and experienced no roll off problems (my mistake). It was the output 1uF cap (C10, C12), driving into a 10K load, that caused excessive roll off. So only the output cap needed to be boosted to 3.3uF.

1/(6.28 x 10000 x .000001) = 15.9Hz (-3dB). So 20Hz would be rolled off by about 2.5dB or so.

@ani_101 said:

Bill, are you doing any modifications to this circuit?

No plans to modify, other than, as Drew indicated above, adding an input cap to block DC from the grid. I am going to experiment using a 1uF 100V panasonic polyester in series with the input jacks.

EDIT: Correction. The 6.4vac below should be 6.8vac.

Powered it up with variac and dim bulb today. No smoke or fireworks. Everything checked out very good except the filament supply voltage. I think I might have a defective full wave bridge rectifier on my heater supply.

Drew, what voltage did you get on your filament supply? I was getting 6.4vac [correction: 6.8vac] on the two white xformer leads, then 7.15vdc after the full wave bridge, then an unregulated 5.43vdc after the LM7806. The 5.43vdc had 134mv of AC ripple riding on it. Then I switched the filament supply over to a 12vac Radio Shack xformer, and was able to get 9.36vac on the inputs by using an 8 ohm 10W dropping resistor in series with one leg of the secondary winding. So now I get 9.36vac at the input, then 9.147vdc after the full wave bridge rectifier, then 5.923vdc after the LM7806 regulator. The 5.923vdc only has 2.3mv of AC ripple riding on it. Heatsink gets warm, but not hot.

@DrewsBrews , here are my voltages by 6J1 tube pin, in case you want to compare it to your build. These are all dc voltage to ground measurements using minigrabbers and my DMM. No signal input, volume control turned all the way down (shorted input). Incoming line voltage was 120vac for all tests. B+ measured 250.2 to 253.3vdc during the testing process.

Pin #1: 0.000vdc (grid) for both channels

Pin #2: 2.44vdc for left channel, 2.71vdc for right channel

Pin #3: 5.43vdc for left channel, 5.47vdc for right channel (using the ali express xformer)

Pin #4: 0.0006vdc for left channel, .0013vdc for right channel

Pin #5: 130.65vdc for left channel, 117.22vdc for right channel

Pin #6: 130.65vdc for left channel, 117.22vdc for right channel

Pin #7: 2.44vdc for left channel, 2.72vdc for right channel

Based on the above, the tube grid is biased at a negative 2.72vdc with respect to the cathode. The idle current flowing through the tube is therefore 2.71ma.

Since I didn't really care about the stock Chinese tubes I just made sure there was no dc on the inputs or outputs before hooking it up to confirm it made sound. I think I did probe the secondary voltages to be sure things weren't way out of wack but I don't remember any numbers. I'll see if I can do some more probing.

Yeah sounds like the 7ish volts is a little too low to allow the regulator to do it's best job. Letting more ripple through. Confirmed since your higher input voltage test puts the output closer to rated 6v. Though is it audible? Is 5.4v too low for the heaters?

I played several music tracks and did not notice any hum caused by this. The 134mv AC ripple on the 5.43vdc is only about 2%, which is not too bad. Probably inaudible.

Yeah sounds like the 7ish volts is a little too low to allow the regulator to do it's best job. Letting more ripple through. Confirmed since your higher input voltage test puts the output closer to rated 6v. Though is it audible? Is 5.4v too low for the heaters?

It seems to work OK at 5.4vdc. This is about 15% below the spec of 6.3vdc. Tubes will probably last longer this way. The tube's transconductance will be somewhat lower when operated at 5.4vdc. This will raise the output impedance of the circuit slightly, but will probably have no effect on either the overall gain or frequency response. I could do some spot FR tests with my scope to verify this. Regardless, I would still like to get the voltage up to 6 and eliminate the ripple.

I thought that perhaps I had a defective full wave bridge rectifier in the filament power supply that was causing an excessive voltage drop. So I removed it and soldering in a different bridge rectifier. The measured voltages, however, remained the same. So I think the bridge rectifier is OK and working like it should. I tested the circuit some more by parallelling 2000uF of additional filter capacitance across the main 3300uF filter cap, boosting it to 5300uF total. This reduced the AC ripple by about 30%, but the output voltage remained at 7.15vdc before the 7806 regulator and 5.4vdc after the regulator.

I think I may also try ordering a 6 or 15 amp bridge rectifier from mouser. If it is small enough to fit the spot on the circuit board, maybe it will have less forward voltage drop under full load conditions. The standard diode drop of .6 volts per diode (totalling 1.2 volts drop for a full wave bridge) would seem to indicate that we should be getting about 8.4vdc before the 7806 regulator, not my measured 7.15vdc. (ie., 6.8vac input x 1.414 = 9.6 - 1.2 = 8.4). But this might be the voltage obtained with no load. Each tube draws about 170ma, so there may be additional losses caused by the 340ma load.

Comments

. . . It appears to spec 2.2uF, but larger may be prudent to allow more bass through? I did test it with 2.5uF temporarily before the 2.2uF caps shipped in. There is plenty of space on the board to accomodate. But be careful when hooking this up to other equipment since there are no input caps. And I don't see any bleeder resistor for the power supply cap/s so the spicy voltage could stick around for quite a while.

I would think that 2.5uF should be more than enough. Just make sure the voltage rating is well above the measured power supply voltage. For instance, if we connect the preamp to a power amp with a 10K input impedance, then the -3dB low frequency roll off point caused by the cap would be 1/(.0000025 x 10000 x 6.28) = 6.37Hz. That should be good enough. I dug through my stash of PP caps and found two Solen 5uF 400 PP caps that fit the PCB perfectly without hitting the ceramic tube socket or RCA jacks. 1/(.000005 x 10000 x 6.28) = 3.18Hz -3dB.

I have an unused Bud box from a previous abandoned project, so I decided to press it into service for my "3rd" build. It is a Bud CU-622-A and measures 12" x 6" x 2.5" (WxDXH). For layout purposes, I temporarily put a few parts on the PCB (not soldered) to see how everything would fit. As viewed from the back, I positioned the xformer on the extreme right hand side and the PCB on the extreme left hand side. This keeps the xformer 7 inches away from the nearest 6J1 tube. I am hoping that this is far enough to avoid any hum pickup issues. I plan to drill four 1/2 inch holes on the left back side of the bud box for the RCA input/output jacks. Then I will cut a larger rectangular hole in the right back side of the bud box for the combo IEC/fuse power inlet.

For the volume control, I plan to add an extension to reach the front panel using a length of 1/4-20 machine screw material cut to the right length (about 2.5" or so). In the photo, I simply taped a 1.5" long flat head 1/4-20 machine screw to the end of the volume control, just for illustration purposes. I will probably need to epoxy a nylon bushing to the front panel to act as a bearing for the extended shaft. Will also epoxy the machine screw to the volume control shaft as well. Hopefully the epoxy will not crack or break off in operation.

I will be using 1/2" tall aluminum standoffs, which gives about a 1/16" clearance to the top of the tube when I put the top cover on. This should work out OK. Some tubes might be a little bit taller, but if they hit the top panel, I will drill two small holes in the top of the Bud box for clearance. I will not be able to see the tube filaments in operation, so I will be adding a pilot light type on/off switch to the front panel. This would go on the extreme right side with short leads to the xformer area.

Let me know what you think of this layout. It is still a work in progress. I plan to populate the PCB today and then drill out the bud box tomorrow.

I think it would look cool if the tube was going out the top. You could mount larger components like capacitors on the bottom to get the tube closer to the top.

Yep, I like to see the glowy things. Maybe put some copper sheet between the tranx and component board?

Looks good! I have some shaft extensions and bushings I could send you, but they won't work with that knurled shaft.

Good idea. I took some measurements and discovered that I can raise the PCB another 3/4" before running into any capacitor or heat sink clearance problems. The tallest item on the PCB, other than the tubes, is the filament power supply heatsink for the 7806 regulator. But if I replace that heatsink with a shorter one, I can raise the PCB as much as 1.25" with no problems.

And put a couple small holes in the sheet to route the wires through. Would copper be better than aluminum or steel? Copper is kind of expensive.

Ya, the slotted, knurled shaft would be crushed by the set screw. My plan is to use some inexpensive "Hillman Fastener" type nylon sleeves and bushings that have an approximate 1/4" ID. I'll cut a slot in the nylon sleeve and slip it over the knurled shaft and extension, then pour some 5 minute epoxy into the slot and joint. If I can keep everything in perfect alignment as the epoxy sets, I should be good to go.

I have seen people use the adhesive lined heatshrink tubing and zip ties to couple shafts.

I'd use whatever was laying around.

gimme a sec...

Very warm? sure. Not so hot that I couldn't leave my finger there indefinitely. I understand, it comes with the heatsink so why not use it right? But if it is a space issue, and leaving it bare makes you uncomfortable; I'd say mounting it to the chassis should give it a nice cushy life.

Thanks, Drew. I agree. It looks like the tall heatsink supplied with the kit is overkill. I have 3 other much shorter T0-220 style heatsinks that I can substitute. Any one of them will fit the existing PCB space and solve the problem.

Edit: Oooops, looks like I have the 7806 in backwards on the pic. It is not soldered in place yet. I accidently put it in backwards before I snapped the photo.

Here is a visual comparison of the original tall heatsink verses a much shorter one. This will allow me to push the PCB up an additional 1/2" or so for a nice tube glowing effect. Almost ready to give it the smoke test.

Original tall heatsink:

Smaller, short heatsink:

Looking good!

Bill , could you have reversed the tube socket install to the bottom of the board to bring those tube out of the chassis a little more? Not sure if that makes sense.

I thought about that too, but the pinout for the tubes would be reversed. Probably easier to just mount the other tall parts from underneath instead.

Sure , absolutely , that makes sense too.

Another possibility would be to install two Jemosa 7 pin tube socket savers. This would raise the tubes an additional 3/4" above the PCB:

https://www.amazon.com/JEMOSA-Vacuum-Socket-Vintage-Amplifier/dp/B0B4Z2B233/ref=mp_s_a_1_10?dib=eyJ2IjoiMSJ9.NuAAqSeqOixqf4jHlwAd2RgR2np0GrgA8VHnwXkVpBaYhXHhyz6Ds-izsVbcTQhBz7NyLgIecrRtaDStnq58i-mhENRGnhtbmOMCB04ZJazXl05llIkpbSATsPrzUt450WlYuF_6eLe2uL12Iu_delGY7UOn3rY4AcgN4EA-AL653_xrzGOJtbfZXxVmTxSKCK9wNmtz4nBoA5lI9WYWGQ.Axg5sko15wLDfb1HvqOXMXvmZDC8PEoOMCCKZzOtvHs&dib_tag=se&keywords=7+pin+tube+socket&qid=1714525047&sr=8-10

Im guessing you already thought this out lol

Bill, are you doing any modifications to this circuit?

If the jacks were left off and wired in remotely, could add input caps in-line. Though I don't know enough about tubes. Is grid impedance influenced by the other operating voltages? If not the original kit updated value of 3.3uf would work? But maybe higher voltage spec to withstand a worse case scenario.

A big thanks to DrewsBrews for giving me this circuit - I don't know too much about tube circuits or any circuits in general. So looking to see if I should go ahead and build it as is or some improvements can be made.

My understanding would be that the input impedance of this preamp would be the 50K pot in parallel with the 1 meg grid resistor (1/((1/1000000+1/50000)) = 47.619K ohms. This resistive input load would be modified somewhat at very high frequencies by the 6J1 tube's plate to grid (miller effect) and grid to cathode capacitances.

So if you placed the input capacitor externally, then the cap would basically see a 47.619K load. Using a 3.3uF input cap, the -3dB low frequency roll off would be 1/(6.28 x 47619 x .0000033) = 1.01Hz. This is overkill. A 1uF cap should be more than enough: 1/(6.28 x 47619 x .000001) = 3.3Hz (-3dB).

On the original 6J1 preamp kit, we did not need to boost the input cap from 1uF to 3.3uF (C9, C11). We could have left it at 1uF and experienced no roll off problems (my mistake). It was the output 1uF cap (C10, C12), driving into a 10K load, that caused excessive roll off. So only the output cap needed to be boosted to 3.3uF.

1/(6.28 x 10000 x .000001) = 15.9Hz (-3dB). So 20Hz would be rolled off by about 2.5dB or so.

No plans to modify, other than, as Drew indicated above, adding an input cap to block DC from the grid. I am going to experiment using a 1uF 100V panasonic polyester in series with the input jacks.

https://www.mouser.com/ProductDetail/Panasonic/ECQ-E1105JFA?qs=E//hvbtCqpP%2BP9rxjtD1Tw==

Thanks, Bill, let us know what works best - will build accordingly

EDIT: Correction. The 6.4vac below should be 6.8vac.

Powered it up with variac and dim bulb today. No smoke or fireworks. Everything checked out very good except the filament supply voltage. I think I might have a defective full wave bridge rectifier on my heater supply.

Drew, what voltage did you get on your filament supply? I was getting 6.4vac [correction: 6.8vac] on the two white xformer leads, then 7.15vdc after the full wave bridge, then an unregulated 5.43vdc after the LM7806. The 5.43vdc had 134mv of AC ripple riding on it. Then I switched the filament supply over to a 12vac Radio Shack xformer, and was able to get 9.36vac on the inputs by using an 8 ohm 10W dropping resistor in series with one leg of the secondary winding. So now I get 9.36vac at the input, then 9.147vdc after the full wave bridge rectifier, then 5.923vdc after the LM7806 regulator. The 5.923vdc only has 2.3mv of AC ripple riding on it. Heatsink gets warm, but not hot.

@DrewsBrews , here are my voltages by 6J1 tube pin, in case you want to compare it to your build. These are all dc voltage to ground measurements using minigrabbers and my DMM. No signal input, volume control turned all the way down (shorted input). Incoming line voltage was 120vac for all tests. B+ measured 250.2 to 253.3vdc during the testing process.

Pin #1: 0.000vdc (grid) for both channels

Pin #2: 2.44vdc for left channel, 2.71vdc for right channel

Pin #3: 5.43vdc for left channel, 5.47vdc for right channel (using the ali express xformer)

Pin #4: 0.0006vdc for left channel, .0013vdc for right channel

Pin #5: 130.65vdc for left channel, 117.22vdc for right channel

Pin #6: 130.65vdc for left channel, 117.22vdc for right channel

Pin #7: 2.44vdc for left channel, 2.72vdc for right channel

Based on the above, the tube grid is biased at a negative 2.72vdc with respect to the cathode. The idle current flowing through the tube is therefore 2.71ma.

Since I didn't really care about the stock Chinese tubes I just made sure there was no dc on the inputs or outputs before hooking it up to confirm it made sound. I think I did probe the secondary voltages to be sure things weren't way out of wack but I don't remember any numbers. I'll see if I can do some more probing.

Yeah sounds like the 7ish volts is a little too low to allow the regulator to do it's best job. Letting more ripple through. Confirmed since your higher input voltage test puts the output closer to rated 6v. Though is it audible? Is 5.4v too low for the heaters?

I played several music tracks and did not notice any hum caused by this. The 134mv AC ripple on the 5.43vdc is only about 2%, which is not too bad. Probably inaudible.

It seems to work OK at 5.4vdc. This is about 15% below the spec of 6.3vdc. Tubes will probably last longer this way. The tube's transconductance will be somewhat lower when operated at 5.4vdc. This will raise the output impedance of the circuit slightly, but will probably have no effect on either the overall gain or frequency response. I could do some spot FR tests with my scope to verify this. Regardless, I would still like to get the voltage up to 6 and eliminate the ripple.

I thought that perhaps I had a defective full wave bridge rectifier in the filament power supply that was causing an excessive voltage drop. So I removed it and soldering in a different bridge rectifier. The measured voltages, however, remained the same. So I think the bridge rectifier is OK and working like it should. I tested the circuit some more by parallelling 2000uF of additional filter capacitance across the main 3300uF filter cap, boosting it to 5300uF total. This reduced the AC ripple by about 30%, but the output voltage remained at 7.15vdc before the 7806 regulator and 5.4vdc after the regulator.

I think I may also try ordering a 6 or 15 amp bridge rectifier from mouser. If it is small enough to fit the spot on the circuit board, maybe it will have less forward voltage drop under full load conditions. The standard diode drop of .6 volts per diode (totalling 1.2 volts drop for a full wave bridge) would seem to indicate that we should be getting about 8.4vdc before the 7806 regulator, not my measured 7.15vdc. (ie., 6.8vac input x 1.414 = 9.6 - 1.2 = 8.4). But this might be the voltage obtained with no load. Each tube draws about 170ma, so there may be additional losses caused by the 340ma load.